Working at Height in the Spring: 10 Ways to Stay Safe

Written by: Jen Adams

Key Takeaway: Be prepared for unpredictable spring weather by keeping the job-site clean,

planning for the forecasted weather, using the right PPE, and taking thorough

safety precautions.

Temperatures may be rising, but spring brings its own set of risks (and borrows some from

winter) that need to be taken seriously. Keep these best practices in mind while you’re working

at height this season to stay safe while enjoying the breeze.

1. Always check the weather.

The only thing consistent about spring weather is that it changes consistently. Be prepared for

the heat or cold by checking the weather ahead of time and plan accordingly, and always be

prepared for sudden changes that could occur.

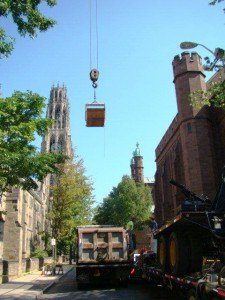

2. Complete thorough safety checks on all large equipment.

With inconsistent weather comes loose earth, mud that gets everywhere, and a higher risk

of rust when equipment is repeatedly soaked and left to dry. Always make sure to check

equipment and machinery before using it and stay up to date on safety regulations by

checking WorkSafeBC.com and using tools like Bigfoot’s Crane Academy.

3. Secure your materials.

High winds can pick up quickly in the spring and are often stronger the higher you work, as the

site is usually more exposed. Make sure the materials you are working with are secure at all

times to avoid injuries or falls from loose materials or objects blowing around.

4. Avoid using power tools in rainy or wet conditions.

Water is an excellent conductor of electricity. By using power tools in the rain or wet after a

rain, you not only run the risk of damaging your tools, but risk electric shock or electrocution if

any wires become exposed while you work. Play it safe and use hand tools where possible or

set up cover over your work area to keep the area dry.

5. Be wary of thunder and lightning storms.

Spring storms are especially dangerous to those working at heights, as lightning is drawn to

metal and tall structures. Monitor the weather report, be aware of your environment, and if the

weather looks dicey, don’t risk working in a storm.

6. Give yourself some traction.

Slipping is always a risk when working on the job-site but becomes even more so when working at

height on wet surfaces. Wear boots and gloves that fit well (make sure they are tight enough that

they can’t slip off, but not so tight as to cut off circulation) and have a lot of traction and grip to

prevent accidents.

7. Always wear appropriate fall PPE, even if working at a lower height.

Most fall-related accidents occur at 30 ft. or less because people view lower heights as less

dangerous, but it takes very little height for a fall to cause injury or even death. Height should be

treated seriously and with caution in any season, but mud and rain make it especially important

to utilize fall PPE in the spring.

8. Let your fall PPE dry naturally before its next use.

Drying equipment with an electric dryer or heater can weaken or melt the material, ruining the

equipment and putting its user at risk. Blot your equipment with towels and hang it up to dry

completely on its own whenever it gets wet, and always check it carefully before each use.

9. Dress warmly enough, and cool enough.

Spring weather may feel warm compared to winter, but its unpredictable nature means that

temperatures can drop to hazardous temperatures, especially when coupled with consistent

cold rains. Dress in layers to ensure you can always keep up with whatever cold or heat the day

throws at you.

10. Train staff to identify weather-based illnesses.

Heat and cold stress occur when the body either warms up faster than it can cool (resulting in

heat exhaustion or sunstroke) or cools down faster than it can warm up (resulting in frostbite

or hypothermia). While they happen more often in summer and winter, they can also strike in

temperatures that don’t seem very extreme. People working at heights can also be at a higher

risk as they tend to be more exposed to the elements. Make sure there are staff on site who are

trained to recognize and treat signs of heat and cold illnesses.

Click here to download: Working at Height in the Spring: 10 Ways to Stay Safe